Data Center Shift with AI

This diagram illustrates how data centers are transforming as they enter the AI era.

📅 Timeline of Technological Evolution

The top section shows major technology revolutions and their timelines:

- Internet ’95 (Internet era)

- Mobile ’07 (Mobile era)

- Cloud ’10 (Cloud era)

- Blockchain

- AI(LLM) ’22 (Large Language Model-based AI era)

🏢 Traditional Data Center Components

Conventional data centers consisted of the following core components:

- Software

- Server

- Network

- Power

- Cooling

These were designed as relatively independent layers.

🚀 New Requirements in the AI Era

With the introduction of AI (especially LLMs), data centers require specialized infrastructure:

- LLM Model – Operating large language models

- GPU – High-performance graphics processing units (essential for AI computations)

- High B/W – High-bandwidth networks (for processing large volumes of data)

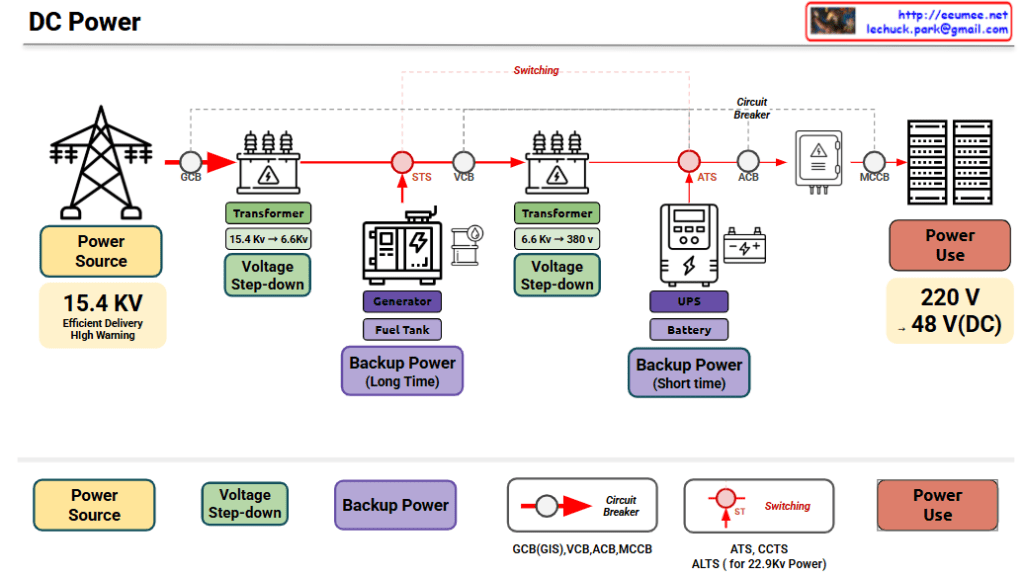

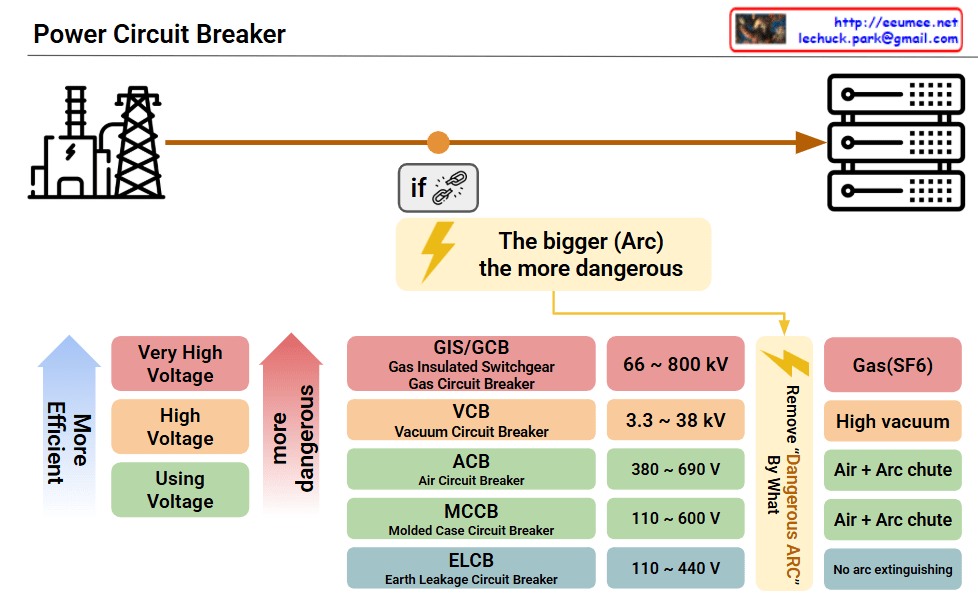

- SMR/HVDC – Switched-Mode Rectifier/High-Voltage Direct Current power systems

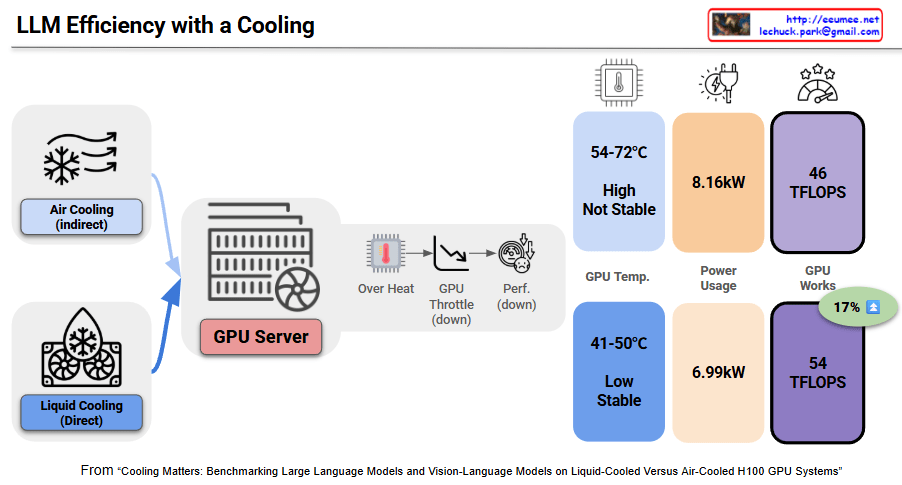

- Liquid/CDU – Liquid cooling/Cooling Distribution Units (for cooling high-heat GPUs)

🔗 Key Characteristic of AI Data Centers: Integrated Design

The circular connection in the center of the diagram represents the most critical feature of AI data centers:

Tight Interdependency between SW/Computing/Network ↔ Power/Cooling

Unlike traditional data centers, in AI data centers:

- GPU-based computing consumes enormous power and generates significant heat

- High B/W networks consume additional power during massive data transfers between GPUs

- Power systems (SMR/HVDC) must stably supply high power density

- Liquid cooling (Liquid/CDU) must handle high-density GPU heat in real-time

These elements must be closely integrated in design, and optimizing just one element cannot guarantee overall system performance.

💡 Key Message

AI workloads require moving beyond the traditional layer-by-layer independent design approach of conventional data centers, demanding that computing-network-power-cooling be designed as one integrated system. This demonstrates that a holistic approach is essential when building AI data centers.

📝 Summary

AI data centers fundamentally differ from traditional data centers through the tight integration of computing, networking, power, and cooling systems. GPU-based AI workloads create unprecedented power density and heat generation, requiring liquid cooling and HVDC power systems. Success in AI infrastructure demands holistic design where all components are co-optimized rather than independently engineered.

#AIDataCenter #DataCenterEvolution #GPUInfrastructure #LiquidCooling #AIComputing #LLM #DataCenterDesign #HighPerformanceComputing #AIInfrastructure #HVDC #HolisticDesign #CloudComputing #DataCenterCooling #AIWorkloads #FutureOfDataCenters

With Claude