Data Center DC Power System Comprehensive Overview

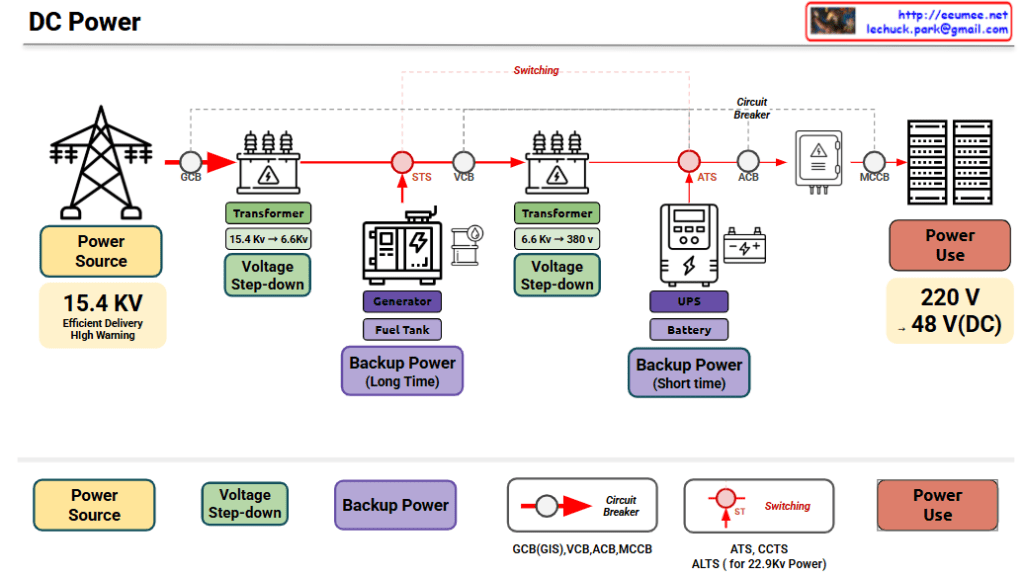

This diagram illustrates the complete DC (Direct Current) power supply system for a data center infrastructure.

1. Core Components

① Power Source

- 15.4 KV High Voltage AC Power

- Received from utility grid

- Efficient long-distance transmission (Efficient Delivery)

- High voltage warning indicator (High Warning)

② Primary Transformer

- Voltage conversion: 15.4 KV → 6.6 KV

- Function: Steps down high voltage to medium voltage

- Transformation method: Voltage Step-down

- Adjusts voltage for internal data center distribution

③ Backup Power #1 – Generator System (Long-Time Backup)

- Configuration: Diesel generator + Fuel tank

- Characteristic: Long-duration backup capability

- Purpose: Continuous power supply during main power outage

- Advantage: Unlimited operation as long as fuel is supplied

④ Secondary Transformer

- Voltage conversion: 6.6 KV → 380 V

- Function: Steps down medium voltage to low voltage

- Transformation method: Voltage Step-down

- Provides appropriate voltage for UPS and final loads

⑤ Backup Power #2 – UPS System (Short-Time Backup)

- Configuration: UPS + Battery

- Characteristic: Short-duration instantaneous backup

- Purpose: Ensures uninterrupted power during main-to-generator transition

- Role: Supplies power during generator startup time (10-30 seconds)

⑥ Final Load (Power Use)

- Output voltage: 220 V AC or 48 V DC

- Target: Servers, network equipment, storage systems

- Feature: Stable IT infrastructure operation with DC power

2. Voltage Conversion Flow

15.4 KV (AC) → 6.6 KV (AC) → 380 V (AC) → 48 V (DC) / 220 V

[Reception] [Primary TX] [Secondary TX] [Final Conversion]

3. Redundant Backup Architecture

Two-Tier Backup System

Main Power (15.4 KV) ─────┐

├──→ Transform ──→ Load

Generator (Long-term) ────┘

↓

UPS/Battery (Short-term) ──→ Instantaneous uninterrupted guarantee

Backup Strategy:

- Generator: Hours to days operation (fuel-dependent)

- UPS: Minutes to tens of minutes operation (battery capacity-dependent)

- Combined effect: UPS covers generator startup gap to achieve complete uninterrupted power

4. Operating Scenarios

Scenario 1: Normal Operation

Utility power (15.4KV) → Primary transform (6.6KV) → Secondary transform (380V) → UPS → DC load (48V)

Scenario 2: Momentary Power Outage

- Main power interruption detected (< 4ms)

- UPS battery immediately engaged

- Continuous power supply to load with zero interruption

Scenario 3: Extended Power Outage

- Main power interruption detected

- UPS battery immediately engaged (maintains uninterrupted power)

- Generator automatically starts (10-30 seconds required)

- Generator reaches rated capacity and replaces main power

- Generator power charges UPS + supplies load

- Long-term operation with continuous fuel supply

Scenario 4: Generator Failure

- Limited-time operation within UPS battery capacity

- Priority operation for critical systems or graceful shutdown

5. Additional Protection and Control Devices

Supplementary devices for system stability and safety:

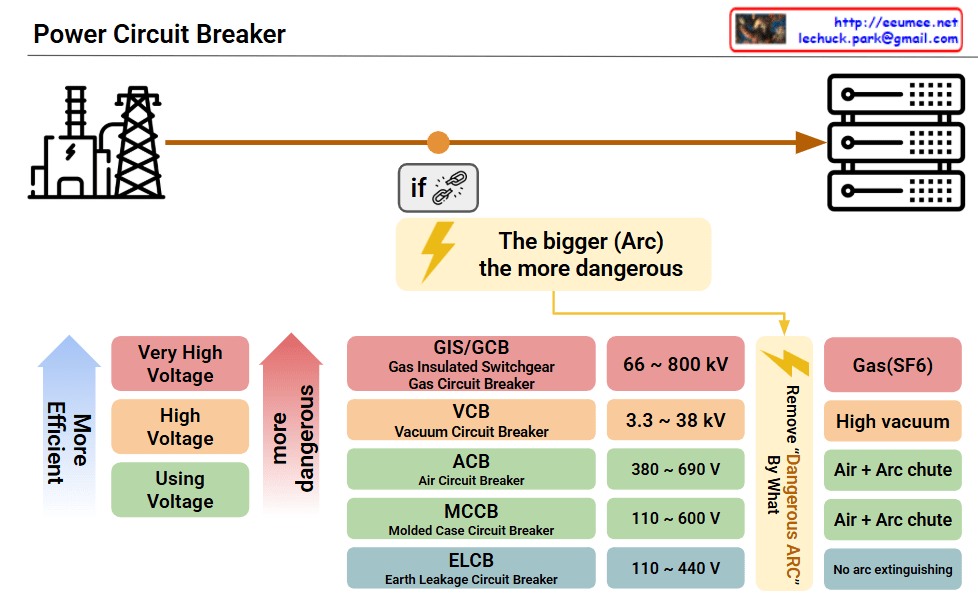

Circuit Breaker Hierarchy

- GCB (Generator Circuit Breaker): Primary protection at reception point

- VCB (Vacuum Circuit Breaker): Vacuum interruption, medium voltage protection

- ACB (Air Circuit Breaker): Low voltage distribution panel protection

- MCCB (Molded Case Circuit Breaker): Individual load protection

- Role: Circuit interruption during overload or short circuit to protect equipment and personnel

Switching Devices

- STS (Static Transfer Switch): High-speed transfer between main power ↔ generator

- ATS (Automatic Transfer Switch): Automatic transfer between power sources ( UPS level)

- ALTS (Automatic Load Transfer Switch): Automatic load transfer ( for 22.9kV class)

- CCTS: Circuit breaker control and transfer system

- Role: Automatic/immediate transfer to backup power during power failure

Switching Points (Red circle indicators)

- Reception point, before/after transformers, backup power injection points

- Critical points for power path changes and redundancy implementation

6. Key System Features

✅ Uninterruptible Power Supply: Three-stage protection with main power → generator → UPS

✅ Multi-stage Voltage Conversion: Ensures both transmission efficiency and usage safety

✅ Automated Backup Transfer: Automatic switching without human intervention

✅ Hierarchical Protection: Stage-by-stage circuit breakers prevent cascading failures

✅ Scalable Architecture: Modular configuration enables easy capacity expansion

Summary

This DC power system architecture ensures continuous, uninterrupted operation of mission-critical data center infrastructure through a sophisticated combination of redundant power sources, automated failover mechanisms, and multi-layered protection systems. The integration of long-term generator backup and short-term UPS battery systems creates a seamless power continuity solution that can handle any grid interruption scenario. The multi-stage voltage transformation (15.4KV → 6.6KV → 380V → 48V DC) optimizes both transmission efficiency and end-user safety while providing flexibility for diverse IT equipment requirements.

#DataCenter #DCPower #PowerSystems #CriticalInfrastructure #UPS #BackupPower #DataCenterDesign #ElectricalEngineering #PowerDistribution #MissionCritical #DataCenterInfrastructure #FacilityManagement #PowerReliability #UninterruptiblePowerSupply #DataCenterOperations

With Claude