The size of innovation is proportional to the number of failures

The Computing for the Fair Human Life.

The size of innovation is proportional to the number of failures

From Claude with some prompting

“Lechuck History” diagram demonstrates the following technical career progression:

Additional key competencies:

This career path and skill set demonstrate the profile of a professional who continuously grows and pursues innovation in a rapidly changing technological environment.

From Claude with some prompting

This image illustrates an Automation process, consisting of two main parts:

The hammer icon represents manual interventions, working in tandem with automated software systems to enhance overall process efficiency. This approach aims to achieve optimal results by combining human involvement with automation systems.

The image demonstrates how automation integrates real-world tasks with software systems to increase efficiency and reduce costs and resources.

From Claude with some prompting

This image illustrates the improvement of work processes through a software system. It’s divided into two parts, with the left side showing manual work and the right side depicting work done through a software system.

Left side (Manual):

Right side (Software System):

The image demonstrates that implementing a software system can simultaneously improve stability and efficiency, and through automation and optimization, achieve significant long-term results.

This diagram effectively contrasts the limitations of manual processes with the benefits of implementing a software system for work processes.

From Claude with some prompting

The image depicts the effects of digitalization in three distinct stages:

Stage 1: Long-Term Accumulated Efficiency Gains Initially, efforts towards digitalization, such as standardization, automation, system and data-based work, may not yield visible results for a considerable amount of time. However, during this period, continuous improvement and optimization gradually lead to an accumulation of efficiency gains.

Stage 2: Eventual Leaps Once the efforts from Stage 1 reach a critical point, significant performance improvements and innovative breakthroughs occur, backed by the experience and learning acquired. The previously accumulated data and process improvement know-how enable these sudden leaps forward.

Stage 3: Extensive Huge Upturn with Big Data & AI Through digitalization, big data is built, and when combined with artificial intelligence technologies, unprecedented and massive levels of performance can be achieved. Data-driven predictions and automated decision-making enable disruptive value creation across a wide range of domains.

Therefore, while the initial stage of digital transformation may seem to yield minimal visible gains, persevering with continuous efforts will allow the accumulation of experience and data, eventually opening up opportunities for rapid innovation and large-scale growth. The key is to maintain patience and commitment, as the true potential of digitalization can be unlocked through the combination of data and advanced technologies like AI.

From DALL-E with some prompting

This image seems to describe the concept of a software system. It emphasizes that the system should not only operate mechanically but must also integrate and understand expert knowledge and human processes through digitalization.

At the top of the diagram, there are images of a computer labeled ‘Just System’ and an expert labeled ‘Expert,’ suggesting that traditionally, systems and human experts operate separately.

In the center, within a large framework labeled ‘Digitalization,’ the ‘System’ and ‘Expert’ are interconnected. This represents the need for systems to understand how machines and systems work and what is desired during the digitalization process.

At the bottom of the diagram, the phrase ‘It’s not just system. All works by systems. So, System must understand real works.’ highlights that the system is more than just mechanical operation; all work is done through systems, and therefore, the system must understand the actual work.

From DALL-E with some prompting

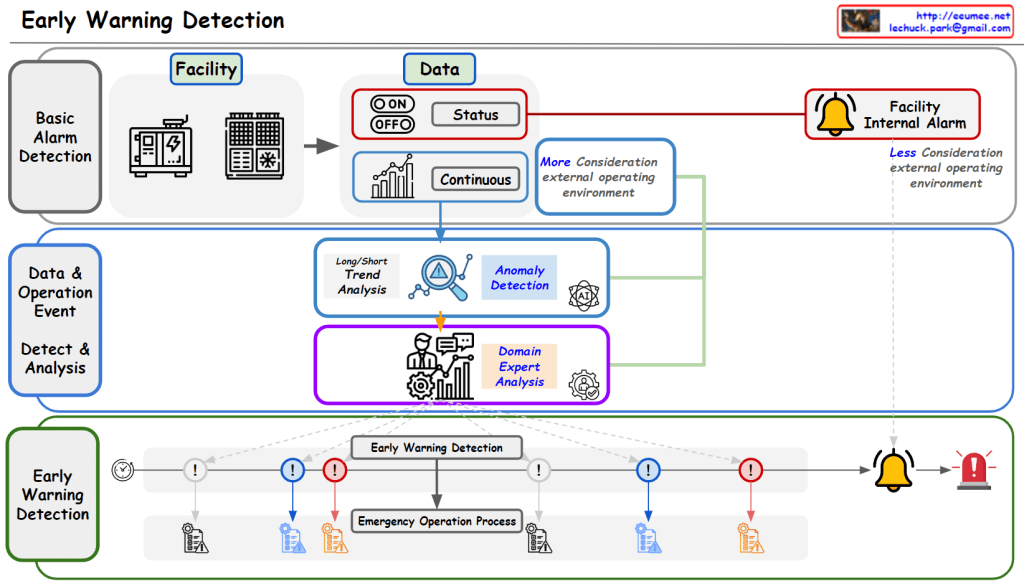

This image illustrates the implementation of an advanced alert system in facilities, extending beyond basic equipment alarms to incorporate data-driven anomaly detection, potentially utilizing AI technologies. The system engages domain experts to analyze data patterns, identifying deviations and planning for event-based responses. These events are systematized with defined levels such as alarms or warnings, and corresponding emergency operation processes are established. By considering the external operating environment, this comprehensive system enhances facility stability and operational efficiency.