From Claude with some prompting

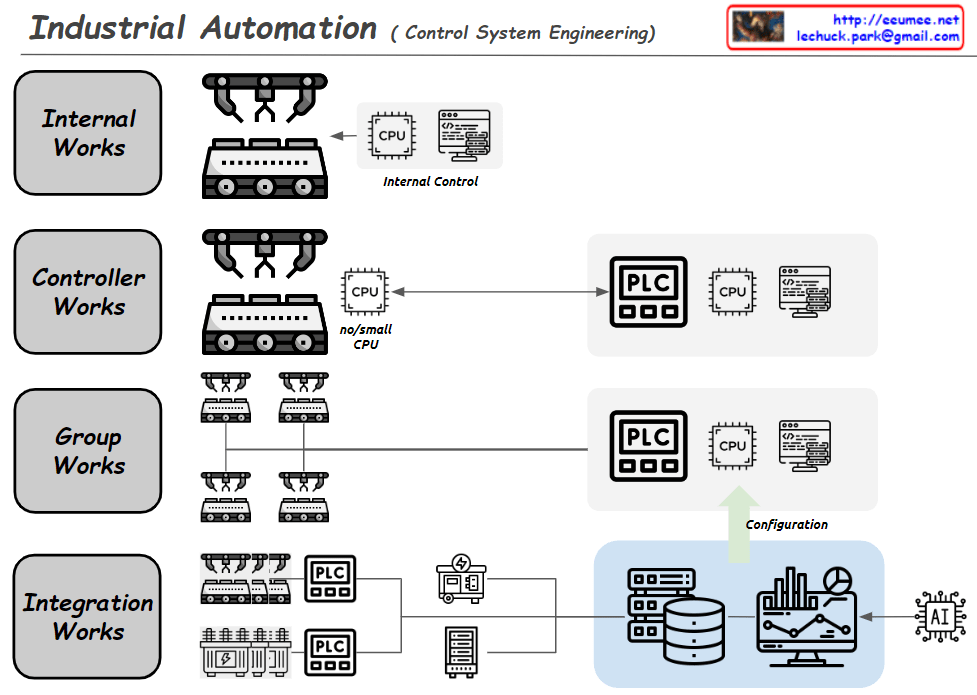

This image depicts the hierarchical structure of an industrial automation system.

At the lowest level, the Internal Works handle the internal control of individual devices.

At the Controller Works level, separate PLCs (Programmable Logic Controllers) are used for control because the computing power of the equipment itself is insufficient for complex program control.

The Group Works level integrates and manages groups of similar or identical equipment.

The Integration Works level integrates all the equipment through PLCs.

At the highest level, there is a database, HMI (Human-Machine Interface), monitoring/analytics systems, etc. This integrated analytics system does not directly control the equipment but rather manages the configuration information for control. AI technologies can also be applied at this level.

Through this hierarchical structure, the entire industrial automation system can be operated and managed efficiently and in an integrated manner.