This diagram illustrates the 3 Core Technological Components of AI World and their surrounding challenges.

AI World’s 3 Core Technological Components

Central AI World Components:

- AI infra (AI Infrastructure) – The foundational technology that powers AI systems

- AI Model – Core algorithms and model technologies represented by neural networks

- AI Agent – Intelligent systems that perform actual tasks and operations

Surrounding 3 Key Challenges

1. Data – Left Area

Data management as the raw material for AI technology:

- Data: Raw data collection

- Verified: Validated and quality-controlled data

- Easy to AI: Data preprocessed and optimized for AI processing

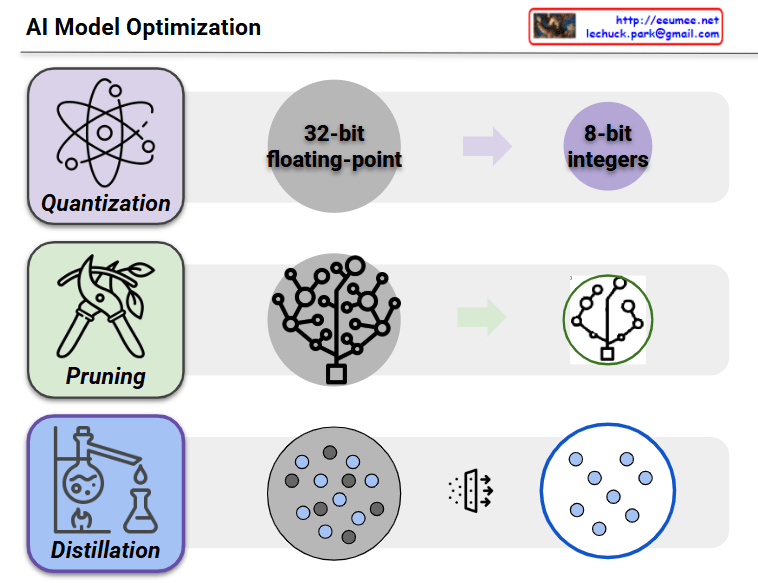

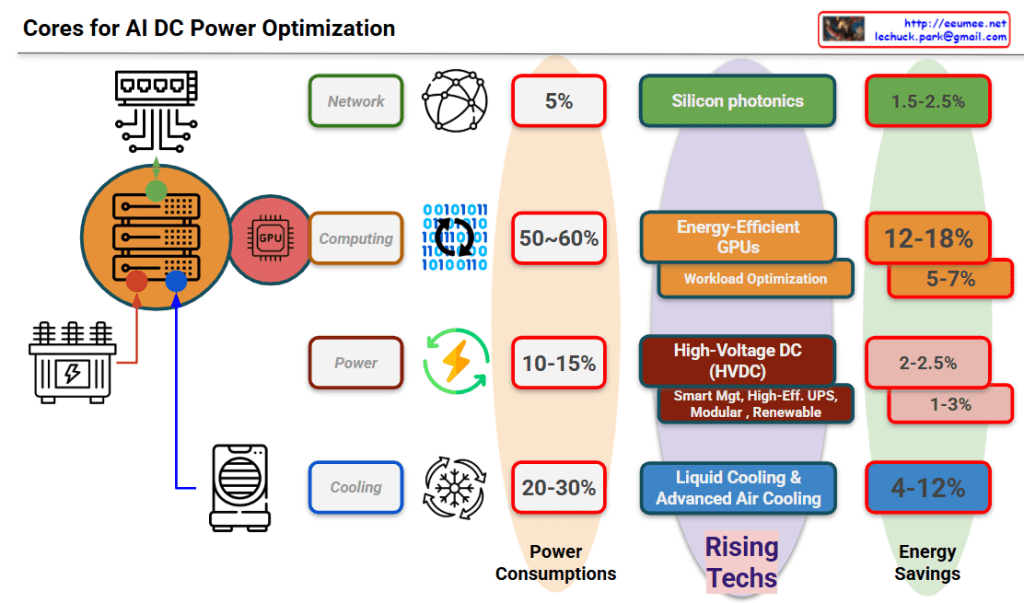

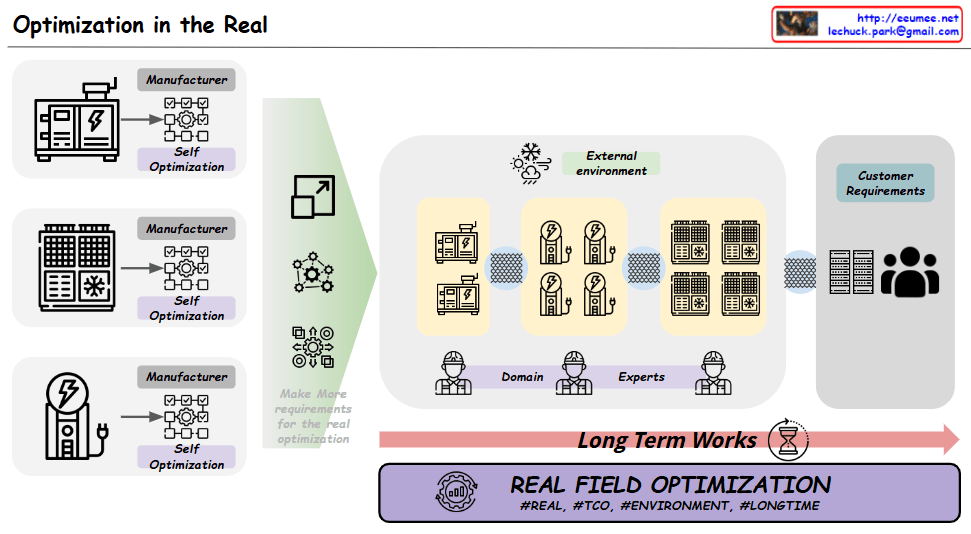

2. Optimization – Bottom Area

Performance enhancement of AI technology:

- Optimization: System optimization

- Fit to data: Data fitting and adaptation

- Energy cost: Efficiency and resource management

3. Verification – Right Area

Ensuring reliability and trustworthiness of AI technology:

- Verification: Technology validation process

- Right?: Accuracy assessment

- Humanism: Alignment with human-centered values

This diagram demonstrates how the three core technological elements – AI Infrastructure, AI Model, and AI Agent – form the center of AI World, while interacting with the three fundamental challenges of Data, Optimization, and Verification to create a comprehensive AI ecosystem.

With Claude