Data Center Cooling System Core Structure

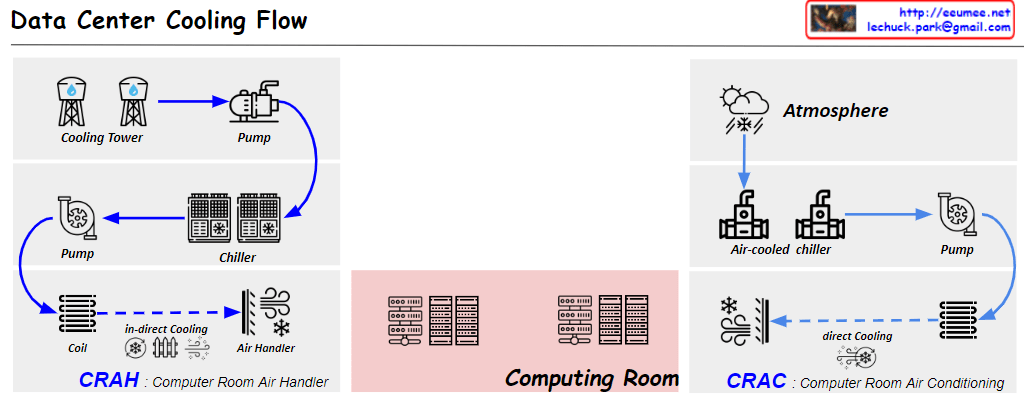

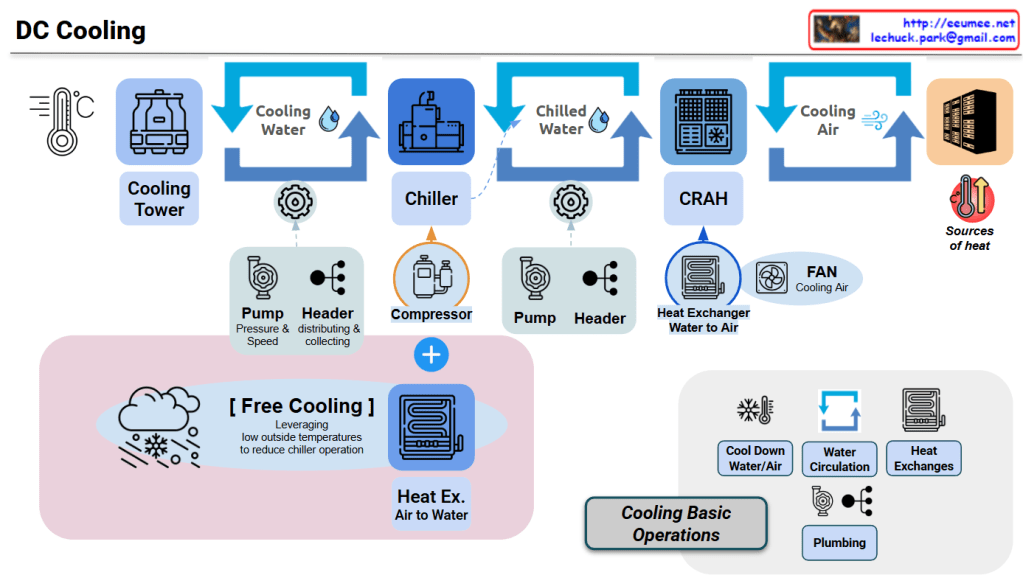

This diagram illustrates an integrated data center cooling system centered on chilled water/cooling water circulation and heat exchange.

Core Cooling Circulation Structure

Primary Loop: Cooling Water Loop

Cooling Tower → Cooling Water → Chiller → (Heat Exchange) → Cooling Tower

- Cooling Tower: Dissipates heat from cooling water to atmosphere using outdoor air

- Pump/Header: Controls cooling water pressure and flow rate through circulation pipes

- Heat Exchange in Chiller: Cooling water exchanges heat with refrigerant to cool the refrigerant

Secondary Loop: Chilled Water Loop

Chiller → Chilled Water → CRAH → (Heat Exchange) → Chiller

- Chiller: Generates chilled water (7-12°C) through compressor and refrigerant cycle

- Pump/Header: Circulates chilled water to CRAH units and returns it back

- Heat Exchange in CRAH: Chilled water exchanges heat with air to cool the air

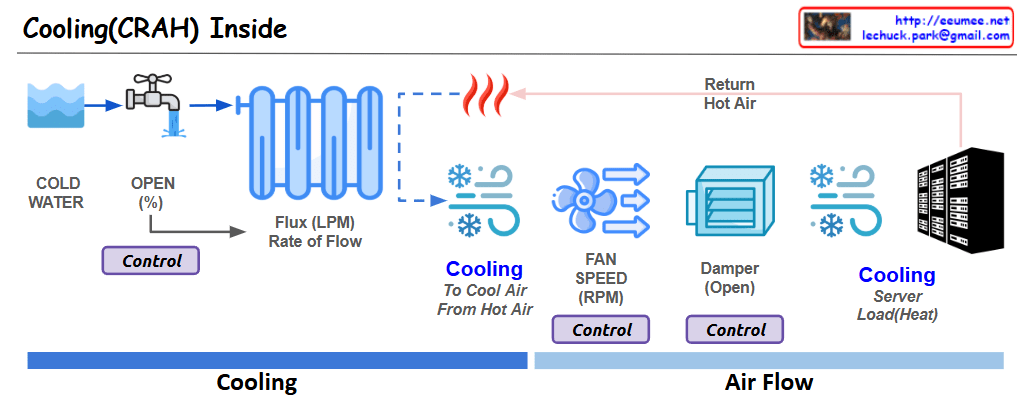

Tertiary Loop: Cooling Air Loop

CRAH → Cooling Air → Servers → Hot Air → CRAH

- CRAH (Computer Room Air Handler): Generates cooling air through water-to-air heat exchanger

- FAN: Forces circulation of cooling air throughout server room

- Heat Absorption: Air absorbs server heat and returns to CRAH

Heat Exchange Critical Points

Heat Exchange #1: Inside Chiller

- Cooling Water ↔ Refrigerant: Transfers refrigerant heat to cooling water in condenser

- Refrigerant ↔ Chilled Water: Absorbs heat from chilled water to refrigerant in evaporator

Heat Exchange #2: CRAH

- Chilled Water ↔ Air: Transfers air heat to chilled water in water-to-air heat exchanger

- Chilled water temperature rises → Returns to chiller

Heat Exchange #3: Server Room

- Hot Air ↔ Servers: Air absorbs heat from servers

- Temperature-increased air → Returns to CRAH

Energy Efficiency: Free Cooling

Low-Temperature Outdoor Air → Air-to-Water Heat Exchanger → Chilled Water Cooling → Reduced Chiller Load

- Condition: When outdoor temperature is sufficiently low

- Effect: Reduces chiller operation and compressor power consumption (up to 30-50%)

- Method: Utilizes natural cooling through cooling tower or dedicated heat exchanger

Cooling System Control Elements

Cooling Basic Operations Components:

- Cool Down: Controls water/air temperature reduction

- Water Circulation: Adjusts flow rate through pump speed/pressure control

- Heat Exchanges: Optimizes heat exchanger efficiency

- Plumbing: Manages circulation paths and pressure loss

Heat Flow Summary

Server Heat → Air → CRAH (Heat Exchange) → Chilled Water → Chiller (Heat Exchange) →

Cooling Water → Cooling Tower → Atmospheric Discharge

Summary

This system efficiently removes server heat to the outdoor atmosphere through three cascading circulation loops (air → chilled water → cooling water) and three strategic heat exchange points (CRAH, Chiller, Cooling Tower). Free cooling optimization reduces energy consumption by up to 50% when outdoor conditions permit. The integrated pump/header network ensures precise flow control across all loops for maximum cooling efficiency.

#DataCenterCooling #ChilledWater #CRAH #FreeCooling #HeatExchange #CoolingTower #ThermalManagement #DataCenterInfrastructure #EnergyEfficiency #HVACSystem #CoolingLoop #WaterCirculation #ServerCooling #DataCenterDesign #GreenDataCenter

With Claude