Digital Twin System Using CFD and AI/ML

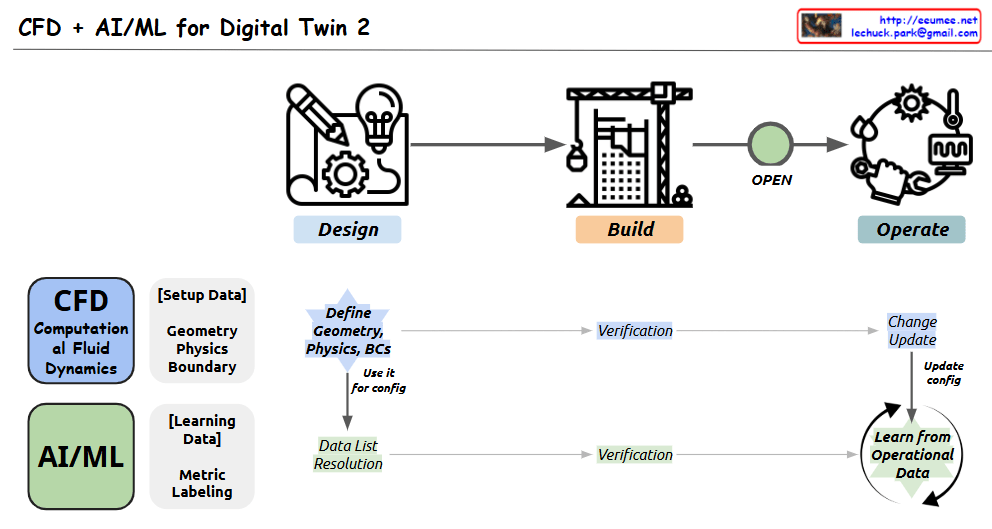

This diagram illustrates the complete lifecycle of a digital twin system, showing how CFD (Computational Fluid Dynamics) and AI/ML play crucial roles at different stages.

Key Stages

- Design:

- CFD plays a critical role at this stage

- Establishes the foundation through geometric modeling, physical property definition, and boundary condition setup

- Accurate physical simulation at this stage forms the basis for future predictions

- Build:

- Implementation stage for the designed model

- Integration of both CFD models and AI/ML models

- Operate:

- AI/ML plays a critical role at this stage

- System performance prediction and optimization based on real-time data

- Continuous model improvement by learning from operational data

Technology Integration Process

- CFD Track:

- Provides accurate physical modeling during the design phase

- Defines geometry, physics, and boundary conditions to establish the basic structure

- Verifies model accuracy through validation processes

- Updates the model according to changes during operation

- AI/ML Track:

- Configures learning data and defines metrics

- Sets up data lists and resolution

- Provides predictive models using real-time data during the operation phase

- Continuously improves prediction accuracy by learning from operational data

Cyclical Improvement System

The key to this system is that physical modeling (CFD) at the design stage and data-driven prediction (AI/ML) at the operation stage work complementarily to form a continuous improvement cycle. Real data collected during operation is used to update the AI/ML models, which in turn contributes to improving the accuracy of the CFD models.

With Claude